Field Service Maintenance • Lake Park Tool & Machine, Inc.

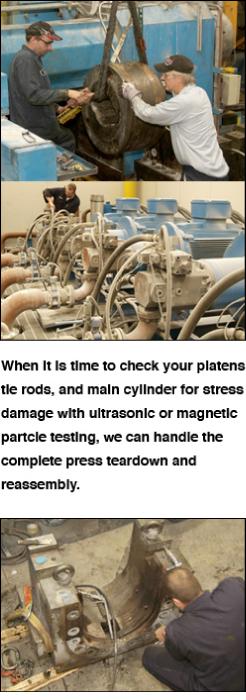

If routine maintenance has your crew stretched beyond its capacity or capabilities, Lake Park can supply the additional resources you need.

Or if you are planning a major maintenance project—and you do not

have enough people to handle it—rely on us for the necessary manpower

and expertise.

We offer press tramming and pre-stressing, press alignment, press

leveling and regrouting, ancillary equipment piping, and fabrication.

Call us for emergency repairs and preventive maintenance of hydraulic, pneumatic, mechanical, and electrical systems. We also provide weld

repair, main cylinder bushing replacement, cylinder rebuilding, tie rod

replacement, and installation.

FIELD SERVICE CAPABILITIES

Welding: |

1/16” to 1/4” stick electrode |

|

Scarfing: |

44 volts at 850 amps |

|

Lance rod: |

Up to 3/4” diameter |

|

Torque: |

5 to 4,475 foot-pounds with 5% accuracy rating |

|

Hydraulic lifting: |

276 tons in Porta-Power rams |

|

Towmotors: |

30 ton to 60 ton lifting capacity |

|

Monorail system: |

Completely portable |

|

Beam and trolley system: |

Four-post, 6” to 14’ in 6” increments |

|

Portable air compressors: |

Max. 175 cfm at 120 psi |

|

Jackhammers: |

Up to 90 pounds |

|

Pipe bending & threading: |

1/8” to 4” diameter |

|

Flaring: |

1/8” to 3/4” diameter |

|

Pipe/tube joining: |

Weld, silver solder, sweat |

|

Skates: |

60-ton machinery rollers |

|

Preheat torches: |

8,000,000 BTU, high efficiency using compressed air |

|

Stress relieving: |

Air vibrators |

|